Home > News

> News Information

Home > News

> News Information

1. Mold alignment unit

The mold alignment unit is also known as the mating guide device for mold blades. In order to ensure the alignment of the upper and lower molds, shorten the preparation time, and meet the requirements of product accuracy and production quantity, there are mainly five types of mold alignment units:

(1) Non guided type: When the mold is installed in the punch press, its blades are directly matched without using a guiding device.

(2) External guidance type: This type of device is a standard structure, and the guidance device is installed on the upper and lower mold bases, without passing through each template. It is generally referred to as the mold base type.

(3) Combination of external and internal guidance (1): This device is a common structure in continuous molds, with an internal guidance device installed between the punch fixing plate and the pressing plate. The fixed pin and external guide device are used for the coordination between the punch and the master mold. Another function of the internal guide device is to prevent the tilting of the pressure plate and protect the small punch.

(4) Combination of external and internal guidance type (II): This device is designed for high-precision and high-speed continuous die use, with the internal guidance device penetrating through the punch fixing plate, pressing plate, mother mold fixing plate, etc. The internal guide device itself also has the function of cooperating with the mold blade and protecting the small punch. The main function of the external guide device is that the mold can be smoothly disassembled and installed in the punch press.

(5) Internal guide type: This structure does not use an external guide device. The internal guide device passes through the punch fixing plate, pressing plate, master mold fixing plate, etc., and correctly maintains the position relationship of each plate to protect the punch.

2. Guide injection and guide sleeve unit

There are two types of mold guidance methods and accessories: (A) external guidance type (mold seat type or main guide type); (B) Internal guidance type (or auxiliary guidance). In addition, according to the requirements of precision molds, there is a high demand for using both external and internal guides in combination.

(1) External guide type: generally used for molds with low precision requirements, most of which are sold together with the mold seat as a unit. Its main function is to align the blades when installing the mold in the punch press, and there is almost no dynamic precision maintenance performance in stamping processing.

(2) Internal guidance type: Due to the development of mold processing machinery, it has rapidly become popular recently. The main function is not only to align the blades when installing molds in the punch press, but also to maintain the dynamic accuracy performance in stamping processing.

(3) Combination of external and internal guidance: A pair of molds use both external and internal guidance devices simultaneously.

3. Punch and master mold unit (circular)

(1) Punch unit: The circular punch unit should match the guide sleeve unit of the press plate according to its shape (shoulder type and flat type), length, and ease of maintenance.

(2) Mother mold unit: Circular mother mold unit, also known as mother mold guide sleeve unit, has two forms: integral and separate, depending on the production quantity, service life, and product or chip handling.

The combination series of master mold units includes: (A) directly processing the shape of the master mold with a template; (B) Having an escape gap with two oblique angles; (C) Whether to use a backboard; (D) The irregular shape of the master mold must have anti rotation design.

4. Tighten the bolt and spring unit

(1) Compression bolt unit:

The types of pressure plate bolts include: (A) external screw type; (B) Sleeve type; (C) Internal thread type.

In order to keep the pressure plate parallel to the designated position, the stopping method of the pressure bolt (shoulder contact part) is: (A) the bearing surface of the mold seat recess; (B) The top surface of the punch fixing plate; (C) The top surface of the punch back plate.

(2) Compression spring unit:

The movable pressing plate pressing spring unit can be roughly divided into: (A) standalone use type; (B) Used in conjunction with compression bolts.

When choosing a compression spring unit, it is best to consider the following points before making a decision: (A) Ensure the free length of the spring and the necessary compression amount (springs with large compression should be placed in the recess of the compression plate). (B) Is it necessary to adjust the initial spring compression (pre compression) or load. (C) Consider the simplicity of mold assembly or maintenance. (D) Consider the relationship with the length of the punch or press bolt. (E) Consider safety (to prevent the spring from flying out when it breaks).

5. Guiding sales unit (positioning of the feeding direction of the material strip).

(1) Guiding pin unit: The main function of guiding pins is to obtain the correct feeding spacing during the continuous stamping process. There are two types of guide units for stamping dies: indirect type (guide pin used separately) and direct type (guide pin installed inside the punch).

(2) The assembly method of the guide pin is the same as that of the punching punch (installed on the punch fixing plate). It is constrained by a punch fixed plate through a spring.

(3) Installing guide pins on the pressure plate requires the guide pins to protrude from the pressure plate to a certain level. When the mold rises, it is easy to carry the processed material, so attention should be paid to the rigidity and guide form of the pressure plate.

(4) The guide pin unit is a direct type, installed inside the punch, mainly used for external punching (material cutting processing) or edge cutting processing in extension engineering. Its position is determined by the product's hole and the inner diameter of the extension piece.

6. Material guide unit

(1) In the process of external stamping (cutting processing) or continuous stamping processing, material guide units are used to guide the width direction of the processed material and obtain the correct feeding pitch.

(2) The guiding device for the width direction of the material strip includes: (a) fixed plate guiding pin type; (b) Movable guide pin type; (c) Board tunnel guide type (single board); (d) Board guided type (composed of two pieces); (e) Lift up sales guide type (movable, fixed, both available).

(3) There are two types of start stop guidance devices: (a) slider type, (b) movable pin type, etc. Its main function is to position the material at the initial starting position of the mold.

(4) The feeding stop device can accurately determine the feeding spacing and is mainly used in manual feeding situations. Its forms include: (a) fixed stop pin; (b) Movable stop pin; (c) Edge cutting stop method; (d) Hook stop mechanism; (e) Automatic stop mechanism.

(5) The side push type material guide mechanism can prevent the snake like phenomenon caused by the difference between the width of the material strip and the width of the guide plate.

(6) There are several forms of guide mechanisms for locating the position of the billet: (a) fixed pin guide type (using the shape of the billet), (b) fixed pin guide type (using the hole of the billet), (c) guide plate (for large components), (d) guide plate (one-piece), (e) guide plate (segmented).

7. Material lifting and topping unit

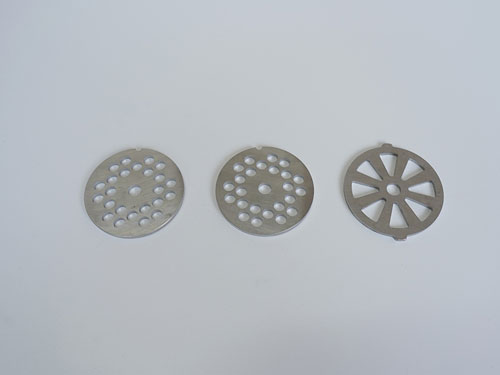

(1) Lift material sales unit: Its main function is to lift the material strip onto the master mold during continuous stamping, and the height of the position is called the feeding height, achieving the goal of smooth feeding. Its form is as follows: (a) The lifting pin type (circular, purely used for lifting) is a common lifting pin unit. (b) The lifting pin type (circular, with holes for guide pins) can prevent the material from being deformed by the guide pins, allowing the guide pins to truly function. (c) The material lifting and guiding pin type has material guiding function. In this form, the guide material of the continuous mold is usually a lifting pin type. (d) If necessary, the lifting pin type (square) is equipped with air blowing holes. (e) Lift and guide pin type (square).

(2) Top material unit: During automatic stamping processing, it is necessary to prevent stamping products or chips from jumping on the surface of the mother mold, to avoid mold damage and poor stamping parts.

(3) Top out unit: The main function of the top out unit is to push the product or waste out of the master mold during each stamping process. The ejector unit has two installation positions: (a) the reverse configuration mold is installed on the upper mold component; (b) The sequential configuration mold is installed on the lower mold component.

8. Fixed sales unit

The shape and size of the fixed pin unit are designed according to the requirements of standard specifications, and the precautions for use are as follows:

(A) The fixed pin hole should be a through hole. If this is not possible, consider a design method that is easy to use for screw disassembly. (B) The length of the fixed pin should be moderate and optimal, and should not exceed the necessary length. (C) Fixed pin holes should have necessary escape components. (D) When placing it in the upper mold component, a mechanism should be designed to prevent it from falling off. (E) When one side is pressed into the fit and the other side slides into the fit, the fixed pin hole on the sliding side is slightly larger than the fixed pin. (F) The quantity of fixed pins should be based on the principle of two, and the same size should be selected as much as possible.

9. Pressure plate unit

An important point of the pressure plate unit is that the parallelism between the pressure surface and the master mold surface is correct, and the buffering pressure needs to be balanced.

10. Error detection unit

When using a continuous die for stamping, the die must be designed with a fault detection unit to detect whether the change in feed spacing exceeds its reference and stop the operation of the punch. The error detection unit is installed inside the mold, and according to its detection method, there are two installation forms:

(a) The upper mold is installed in the form of a detection pin. When it deviates from the hole of the material strip, it will come into contact with the material strip for detection. (b) The lower mold is equipped with a detection pin, which detects when a part of the material strip comes into contact with the detection pin.

Recently, the detection methods using contact methods will undergo changes, with an increasing trend towards the use of proximity switches. The detection pin installed in the upper mold is a standard detection device. Since it is detected near the bottom dead center, there is a time deviation from the start of detection to the stop of the punch press, making it difficult to achieve the anti error effect completely. The detection device installed in the lower mold can directly detect materials immediately after the material feeding action is completed, and this method has received attention.

11. Waste cutting unit

In the continuous stamping process, the material strips (waste) will leave the mold one by one, and there are two processing methods: (a) coiling with a coiling machine, and (b) thinning with a mold cutting device.

The latter has two ways: (a) using a dedicated waste cutting machine (installed outside the stamping machinery), (b) installing cutting units in the final project of the continuous mold.

12. Height stop block unit

The main function of the height stop block unit is to correctly determine the position of the upper die bottom dead center. There are two forms: (a) frequent contact during stamping processing, and (b) contact only during assembly and no contact during stamping processing. In addition, to prevent contact between the upper and lower molds during transportation and storage, it is best to place a spacer between the upper and lower molds. When precision is not required, the standard can be screw adjustable.

.jpg)