Home > News

> News Information

Home > News

> News Information

1、 Standard structure and function of punching die

Punching die: refers to a general term for molds such as punching, cutting, and trimming.

Before starting the structural design of the mold, the above standard structure should be determined first. When special parts (such as thick parts or high hardness materials) are not suitable for using the above standard structure, two heat treatment pads can be added on this basis.

The working process of the punching die is divided into the following parts according to the movement sequence of the punch press:

1. The punch slider drives the upper mold to move downwards from the high point of the open mold state, while the upper and lower molds are not in contact.

2. When the upper striking plate comes into contact with the lower die punch, the upper striking plate stops moving, and the punch slider continues to move downward. The upper die release spring begins to compress, and the spring presses against the upper striking plate, compressing the stamped part. After a certain distance, the punch installed on the upper clamp plate comes into contact with the punch.

3. The punch slider continues to move downwards, and when it approaches the bottom dead center (closed mold state), all the punches enter the lower mold hole to complete the punching.

4. Punching waste falls from the lower template onto the lower cushion plate and onto the leakage hole of the lower mold seat.

5. After the punch passes through the bottom dead center, the punch slider drives the upper mold to start picking up. At this point, due to the release of pressure, under the action of the upper die release spring force, the upper punching plate will eject the punch from the punch, completing the material dropping. Lower the top material pin of the template and top it up, so that the punch piece returns to its original position.

6. The punch slider drives the upper mold to continue upward, returning to the high point when the mold was opened, completing the stamping process in one go.

be careful:

1. The height of the closed mold should conform to the corresponding height of the closed mold of the selected punch press.

2. When the outer positioning block and inner positioning pin are used simultaneously, the outer positioning is coarse and slightly higher than the inner positioning.

3. The corresponding thickness of each template should refer to and comply with the Flextronics Mold Design Standards.

2、 Design of punching die

1) Enter command T1 in the CAD command bar, and the following dialog box will pop up. Manually enter the relevant information of the template and the closing height, and then click the OK button. (The information entered here will help us automatically generate the content of TOMB after the design is completed)

2) Determine the size of the template based on the layout diagram and copy it to the corresponding layer. Enter command T2 in the CAD command bar, and the following dialog box will appear. Then click the corresponding button to automatically generate template elements for the corresponding layer. If the template is relatively large, you can complete the partitioning work later.

3) Start drawing the punching, positioning, avoidance position and other work contents, and draw detailed side views of the punching, positioning and other work contents in the SID VIEW previously drawn. After completion, the work of dividing the board can be carried out. If the size of the template does not exceed the dimensions specified in the Flextronics mold design standards, there is no need to divide the template. By clicking the Generate Punch button in the CAD toolbar, a dialog box can be obtained, and automatic drawing of punching can be completed by manually entering information.

If the punch to be stretched is not suitable for automatic stretching generation, such as large irregular punch heads that need to be fixed with screws. You can click the button on the toolbar to call the dialog box, and then automatically complete any form of automatic drawing of the strengthening punch.

4) Layout of components such as top material pins, floating blocks, and limit blocks: Top material pins, floating blocks, limit blocks, and other components must use the standard pattern in the template file, and the limit blocks should preferably be square. When using limit blocks in engineering molds, they must be divided into upper and lower parts, and the size value of B must not exceed the height of the lower template. The dimension height of A B must be 0.1 millimeters smaller than the actual closed mold height value.

5) Adjust the size of the upper and lower load-bearing plates, spring plates, and the position of the upper and lower pads, and draw a feeding groove on the lower pad. The feeding groove on the lower pad is clamped at a 60 degree angle.

6) Layout of hardware components and closed molds; When arranging hardware parts (such as screws, pins, spindles, etc.), a dialog box will pop up, requiring manual input of corresponding specifications (such as size, length, etc.) information for the hardware parts. The list of hardware parts will be automatically generated based on this information. The size of the template fixing screws should be M10 with a spacing of 150-250 millimeters.

7) Perform self inspection on the structure and check one by one according to the final design re inspection form to reduce routine errors. After completing this form, it needs to be kept properly until all drawings are signed and approved.

8) Add a frame to the image file, fill in the frame content, and compile TOMB;

Before starting the design, we carefully edited the relevant information of each template. Now, we can use the Q-TOMR button in the dialog box to quickly complete TOMB compilation for templates only. Then other functional buttons can be used to complete the compilation of the relevant TOMB parts.

9) Generate BOM tables such as STOCK LIST, STANDARD LIST, SCREW LIST, PERF CHART, etc; Use the STOCK LIST.STANDARD LIST and SCREW LIST buttons in the dialog box to automatically generate the corresponding tables.

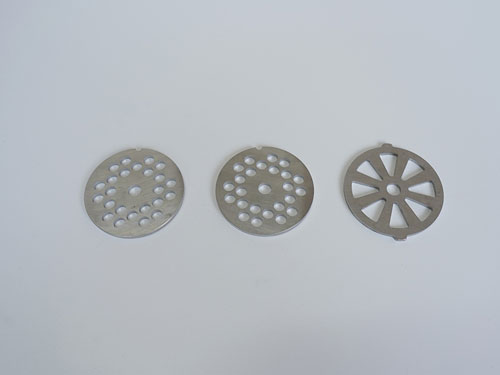

Clicking the button on the toolbar will display a dialog box, and then clicking the "PERF LIST" button will automatically generate a list of all punching related items.

10) Check and dismantle drawings

After completing the overall layout design and generating all tables, it is necessary to submit the design drawing inspection record table and the entire design to LEADER for inspection, and then modify any unreasonable parts.

After the modification is completed, the drawing can be disassembled, and the specific operation method needs to refer to the LDS course textbook and Flextronics mold design standards.

3、 Sign off and produce drawings

1) Check whether the disassembled and printed drawing files are newly revised drawing files, whether the drawings are consistent with the drawing files, and whether there are any omissions in the saved drawing files. Check whether the drawing files and drawings are complete. Hand it over to the supervisor for signature.

2) Put the signed electronic drawings into the exchange area, fill out the drawing distribution and bidding list to complete the design.

.jpg)